General Manoj Mukund Naravane (r)

The Defexpo held at Gandhinagar from 18 to 22 October 22 was unique and probably the first of its kind for India and even the World. The uniqueness of this Expo was that it only featured indigenous companies, be it Defence Public Sector Undertakings (DPSU), recently revamped entities of the erstwhile Ordnance Factory Board (OFB), key players in the defence industry, and a wide array of Micro, Small and Medium Enterprises (MSME) and start-ups from all across the country. The Defexpo had more than 1300 exhibitors who rallied to the theme of the expo, namely, ‘Path to Pride’.

What was very heartening to note, too, was the large turnout from amongst the locals on the 21 and 22 October, which were the ‘public’ days. Huge crowds thronged all the pavilions, and there was a profusion of children in their school uniforms and, of course, National Cadet Corps (NCC) cadets keenly observing and, where permitted, handling the various items on display. At the Zen Technologies enclosure, where an indoor firing simulator was displayed, I got one girl and a boy to test their skills. I have to report that the girl cadet won hands-down.

Since I, too, had gone on the public days, it gave me an opportunity to spend much more time in each of the stalls and to interact directly with the persons actually and actively involved in the projects and products, rather than the Chief Executive Officers, Directors etc. It also enabled giving unbiased advice and recommendations to the executives demonstrating their products. Unfortunately, this was not the case while in service, when time was at a premium and surrounded by a bevvy of security personnel.

What stood out loud and clear was how far our indigenous defence industry has progressed in all fields. It was all there, from small arms and ammunition to larger weapon platforms. Moreover, it was not confined to conventional platforms but included products integrating cutting-edge and futuristic technologies, including Machine Learning (ML) and Artificial Intelligence (AI). Drone and counter-drone systems were ubiquitous. There was a swarm of them!

Efforts being put into research and development (R&D) were also very much evident. However, one facet that was perhaps lacking was the aesthetic aspect. The product must appeal to the user. There is a feeling that once the essential Qualitative Requirements (QR) are met, the rest will follow. That is not necessarily the case. Perception matters. Take the case of the INSAS Rifle vis-à-vis the AK series of rifles or of the Arjun tank vis-à-vis the T-90. The user preference for the latter was subjective and only a matter of branding. Design and ergonomics play a vital role in this regard. Involving end-users from the rank-and-file, right from the drawing board stage, might be a good idea.

Similarly, those involved in the R&D must also visit units and formations where their products will end up to get a feel of the ground. Such close interaction and interactive development will be the key to producing a world-class product capable of spiral development. This is especially important, as products on the drawing board stage today will have to remain at the cutting edge well into the second half of this century, despite technological advances. The ability to absorb new and emerging technologies into legacy platforms will be paramount.

It was indeed heartening to see a large number of MSMEs present at the expo. Typically, the prime space in the centre of the pavilions is taken up by the more prominent players and attracts the maximum footfall. The smaller MSME kiosks on the periphery hardly get more than a passing glance. Having gone later, however, it was possible to do justice by visiting these, whose owners were equally keen to showcase their products.

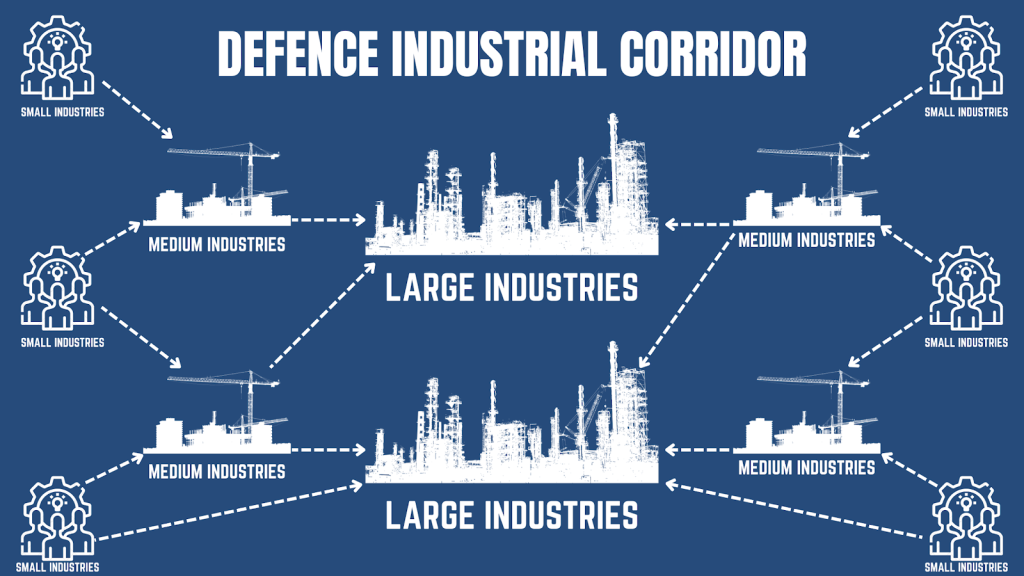

One of these, based in Noida, was manufacturing automobile parts and ancillaries and supplying these to all the major companies making mine-protected vehicles for the Indian Army. Just imagine one small company feeding three larger ones. Such is the strength and capability of our MSMEs, which needs to be further harnessed. Similarly, companies based in Kolkata were suppliers to companies based in the Southern part of India, and vice-versa.

While such diversification is good, it nevertheless lengthens the supply chain. This increases costs and is more at risk of disruptions, as was amply demonstrated during the Covid crisis. If all the smaller companies feeding the larger ones could be co-located within a given geographical area, it would bring in more efficiencies. It would cut not only costs but also increase productivity. In the kite-making industry in Gujarat, for example, the paper used to come from one location, the glue to stick the papers together from a second, the string used to make the twine from a third and so on.

When Prime Minister Narendra Modi was the Chief Minister of Gujarat, all these disparate activities were consolidated into adjacent areas, and this simple step initiated under his guidance boosted productivity manifold. A similar stratagem can be adopted for the Defence Industrial Corridors in Tamil Nadu and Uttar Pradesh. The ecosystem should be so raised that various factories and plants feed the next one in the value chain till the final system integrator, making them co-dependent and mutually supportive.

Of course, business needs and runs on money. All the entrepreneurs and even the bigger players were looking at firm orders from the Services. Many smaller start-ups have exhausted their capital in reaching the prototype stage. They now need a fresh infusion of capital to remain afloat. This would only be possible if firm orders are placed, even for bare minimum quantities, using delegated powers and other fast-track procedures.

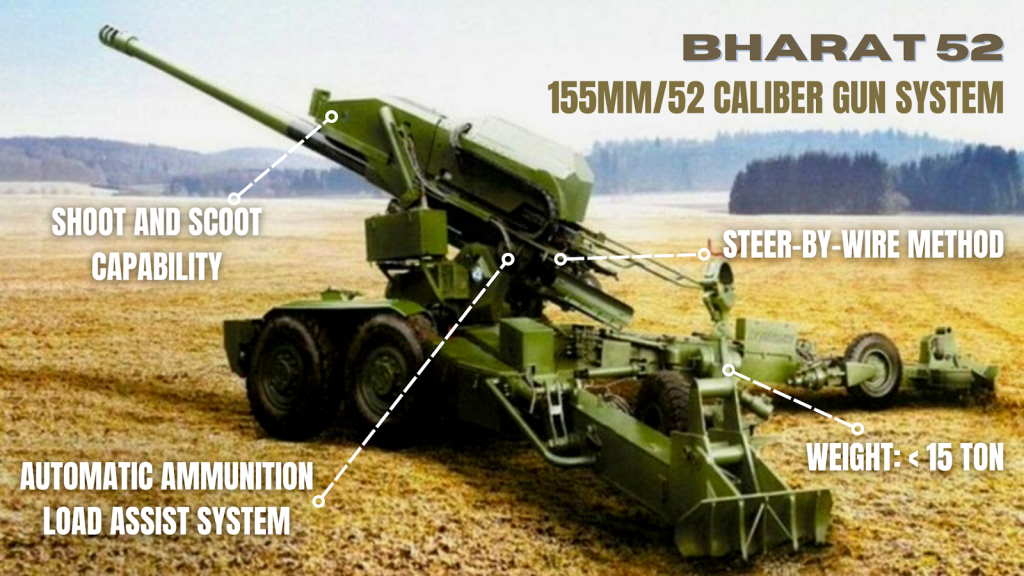

However, it must be understood that the domestic market will always be finite. Hence the defence industry as a whole will have to look towards exports if they have to remain profitable. The order bagged recently by Kalyani Strategic Systems Ltd for the export of a 155mm Mounted Gun System to the tune of USD 155 million (Rs 1,265 crore) is a step in the right direction and the coming of age of the ‘Make in India’ initiative.

Major foreign companies earn their profits from sales to third countries. We have made steady gains in this regard, with India registering defence exports worth Rs 8,000 crore in the first six months of the current financial year (FY 2022-23) with the ultimate aim to achieve an annual export target of Rs 35,000 crore by 2025. In order to accomplish this, a more concerted and coordinated approach is required. To this end, it might be worthwhile to include an industry representative as part of Service delegations going abroad, especially those led by the Service chiefs and Chief of Defence Staff (CDS).

The wide range of equipment on display showed that many companies were developing the same or similar products. Therefore, it was obvious that there was an immense amount of duplication of effort at the grass-root level. R&D is an expensive proposition; only some projects are successful and converted into firm orders. Ultimately, the final order will only be placed on a single company, which emerges as the most competitive in the bidding process. So rather than competing amongst themselves, companies may consider forming consortiums to share the developmental costs.

There could be two or three major consortiums (for the sake of competition and avoiding single vendor situations) comprising a number of complementary companies, who will collectively benefit by pooling in their resources and expertise. These consortia could then participate in various tenders as one entity, which will have the added advantage of significantly facilitating and speeding up the procurement process.

The ‘Make in India’ initiative has certainly galvanised the Indian defence ecosystem. If we have to achieve our stated export target of Rs 35,000 crores, we cannot afford to get blocked by ‘bureaucratic cholesterol’ and have to be more outcome driven. Product, not Process, should be the Priority. It is now up to all stakeholders, starting from the Ministry of Defence (MoD) down to the smallest start-up, to work together and make our country renowned in the field of Defence Production as we walk down the ‘Path to Pride’.

Gen. MM Naravane (r) served as the 27th Chief of Army Staff